|

|

|

|

|

CONVEYOR PRODUCTS - Info

|

|

|

| Our Conveyor Products are Australian Made. Our designs are very flexible, they can be supplied with various outputs like 4 - 20mA and can include local or remote displays and alarms. Our designs are flexible and practical operating from various DC and AC Power Supplies. Whether your weighing or tensioning on a Conveyor we can handle your project with our equipment.

|

|

|

|

|

CONVEYOR PRODUCTS

|

|

|

| |

Gravity Systems

|

|

It is common to find the gravity rollers exerting a larger weight or tension onto the conveyor belt due to a build up of dirt and dust. We have known 30 tonne rollers to increase in weight to 45 – 50 tonnes. Obviously this is not the best situation. This additional weight could cause the conveyor to fail and most certainly causes un-necessary wear and tear of the conveyor system. .

Monitoring the tension in a gravity roller system is a sensible approach to maintainimng your conveyor in the best possible condition."

|

|

|

|

| |

In-Motion Weighing

|

|

Australian designed belt weighers. The Modular Belt weigher system offers a common solution for simple ""control"" weighers to highly accurate multi idler weighers. The modular design allows a common weigher design which suits a wide range of conveyor widths and accuracy requirements and should the requirements change, the weigher can be easily relocated or reconfigured.

All models feature a fully floating weighbridge that is restrained against the movement of the conveyor belt by a system of parallel stainless steel leaf springs with require no routine maintenance or adjustment. The unit features a stainless steel load cell with overload protection mounted under the weigher, protected from falling debris material build up. The design allows the simple addition of calibration weights, both manually applied to the weigher and stored in convenient test weight receptors, or, for the test weights exceeding 25kg, the calibration weight is applied via lever arm actuation. As most gantry conveyors only have access walkways on one side, the calibration weigh systems, manual or lever arm only require access from one side.

The single idler model MBS belt weigher is designed with one load cell for belt widths to 1500mm wide and with two load cells for wide belts with the possibility of high side forces.

The Multi idler MBD belt weigher is designed for applications requiring two or more weigh idlers. The unit is constructed from heavy gauge PFC sections and plate steel mounted on edge, thus reducing surfaces that can acquire material build up. The MBD is designed from standard modules configured to offer the premium solution for each specific application.

Contact us for application and installation recommendations data sheet for single and multi idlers belt weighers, or contact us to arrange one of our engineers to review your specific application."

|

|

|

|

| |

Take-Up Winches

|

|

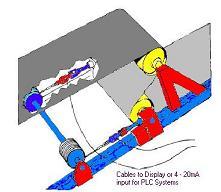

Load Cells are installed on either side of the conveyor. They are connected to a take-up winch, which applies tension onto each side of the conveyor belt. The Load Cells monitor the take-up winches. This System provides a read-out of the tension on each side of the conveyor. Various communications outputs i.e. 4 - 20mA signal, RS485 etc are available.

Our system enables the maintenance department to accurately adjust and set the tension on each side of the conveyor belt."

|

| PDF Document for: Take-Up Winches |

|

Item: |

Take-Up Winches |

| Size: |

24.16 Kb |

|

|

|

|

| |

|

|

|

|